|

<< Click to Display Table of Contents >> Gravel Pack Completion Data: |

|

|

<< Click to Display Table of Contents >> Gravel Pack Completion Data: |

|

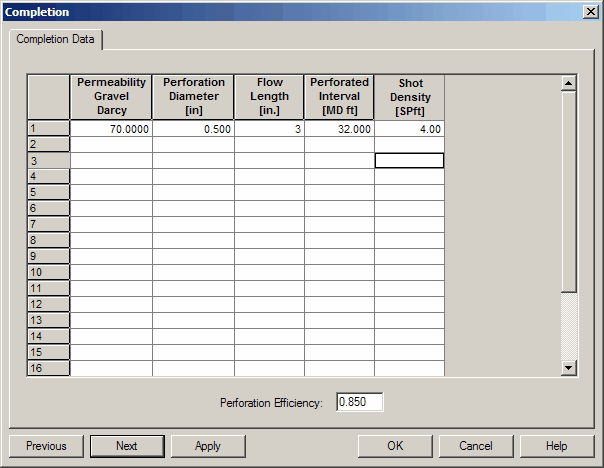

Gravel Pack Completion Data

Note: This analysis method is designed around the CASED gravel pack model and should not be used for open hole gravel packs. If warranted, the Open hole gravel pack model can be added to a future program version by calling the program contact.

GRAVEL PERMEABILITY (Darcys): This number depends on the gravel mesh size. Typical values are given in the following table:

Gravel Mesh Size |

Permeability (Darcys) |

8 – 12 |

1000 |

10 – 20 |

400 |

20 – 40 |

120 |

40 – 60 |

70 |

Note that the actual in-situ permeability of the gravel pack may be lower due to fines and other contaminants. A reduction of 50% is recommended in the literature

PERFORATION DIAMETER (in): The average diameter of the perforation through the casing, cement sheath, and formation. It depends on the charge and the gun used. The API RP-43 certification data for the specific charge should provide an upper bound on this variable. Typical values range from 1/2" to 7/8".

FLOW LENGTH (in): The linear distance that fluids flow through the defined gravel pack. This is most often the hole radius minus the screen radius. If you feel that flow is linear through the perforation tunnel as well, that should be included. The first method is recommended i.e., Rh - Rs. Another way to describe the flow length is the distance between the outside of the cement sheath and the outside of the screen. It can be calculated from :L = rw - 0.5 * ds

where: L - flow length (in), rw - wellbore radius (in), ds - outside diameter of the screen (in)

PERFORATED INTERVAL (ft): The length of the perforated section of the zone of interest. It is obtained from the completion report. More than one zone may be present and open to the wellbore. Each zone will have a unique perforated interval.

SHOT DENSITY (spf): The design or specified number of perforations to be shot per foot. This number is reduced in the program by the entered perforation efficiency.

PERFORATION EFFICIENCY: In most cases, perforating is not 100% effective in creating a flow path to the formation. The probability of a successful perforation is the probability of a good fire times the probability of the perforation completely traversing the casing, cement and damaged zones. A typical efficiency value is 0.5 to 0.9.