|

<< Click to Display Table of Contents >> Perforated Cased Hole Data |

|

|

<< Click to Display Table of Contents >> Perforated Cased Hole Data |

|

Perforated Cased Hole Data

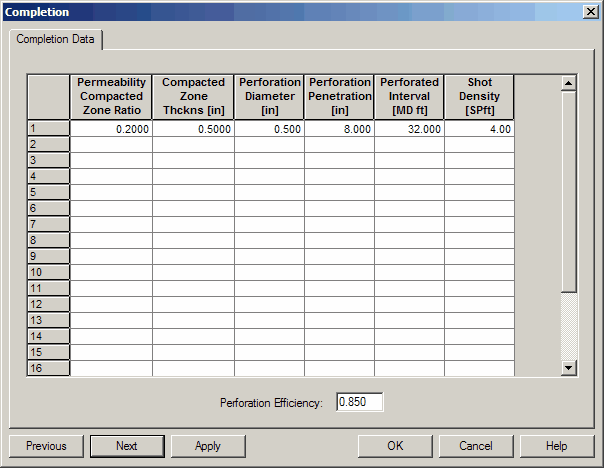

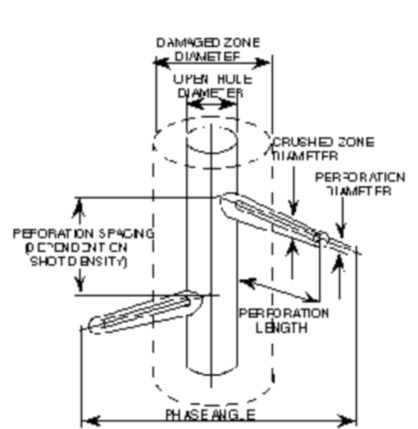

COMPACTED ZONE PERMEABILITY RATIO: It is documented in the literature that perforating with shaped charges creates an area of reduced permeability or damage around each perforation. The resulting permeability may range from 10 to 50 percent of the original permeability depending on whether the well is perforated over-balanced or under-balanced. Perforating under-balanced causes less damage and yields higher permeabilities. The recommended value for the ratio of the compacted zone permeability to the original permeability is 0.2 (20%).

COMPACTED ZONE THICKNESS (in): The thickness of the reduced permeability zone around each perforation. This is caused by the perforating process which creates a compacted or damaged zone with lower permeability. A value of 0.5 is recommended.

PERFORATION DIAMETER (in): The average diameter of the perforation through the casing, cement sheath, and formation. It depends on the charge and the gun used, as well as on the formation strength. The API RP-43 certification data for specific charge provide an upper bound for this variable.

PERFORATION PENETRATION (in): The average depth of penetration into the formation not counting pipe or cement thickness. It depends on the charge and the gun used as well as on the formation strength. Subtract cement and pipe thickness from published penetration depths. The model used to predict perforation pressure drop assumes radial flow into the perforation from a porous media. For this reason, cement and pipe thickness should not be included.

PERFORATED INTERVAL (ft): The length of the perforated section of the zone of interest. It is obtained from the completion report and is independent of formation thickness. For a fully perforated deviated well, the perforated interval may be longer than the zone thickness.

SHOT DENSITY (spf): The design or specified number of perforations to be shot per foot. This number is reduced in the program by the entered perforation efficiency.

PERFORATION EFFICIENCY: In most cases, perforating is not 100% effective in creating a flow path to the formation. The probability of a successful perforation is the probability of a good fire times the probability of the perforation traversing the casing, cement and damaged zones. A typical efficiency value is 0.5 to 0.9 (50% to 90%).