|

<< Click to Display Table of Contents >> Hydraulics Correlations |

|

|

<< Click to Display Table of Contents >> Hydraulics Correlations |

|

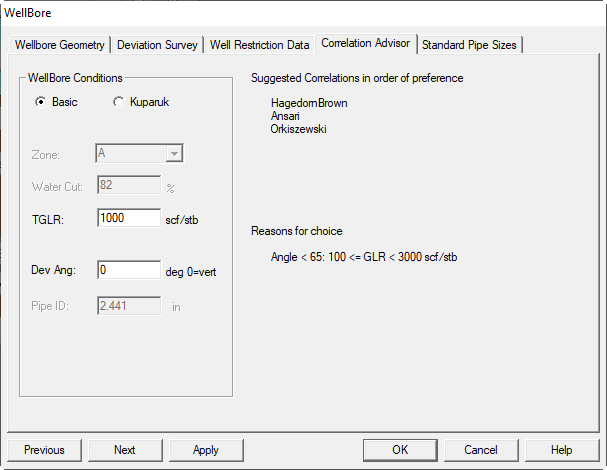

Hydraulics Correlation Advisor

This dialog allows the user to select the hydraulic (multiphase) correlation to be used in the calculation of the tubing and flowline curves.

Vertical Correlations:

Hagedorn & Brown

The Hagedorn and Brown correlation was developed following an experimental study of pressure gradients occurring during continuous two-phase flow in small diameter vertical conduits. A 1,500 ft experimental well was used to study flow through 1-in, 1.25-in, and 1.5-in nominal size tubing. Tests were conducted for widely varying liquid flowrates, gas-liquid ratios and liquid viscosities. All of the correlations involve only dimensionless groups, which is a condition usually sought for in similarity analysis but not always achieved.

Hagedorn, A. R. and Brown, K. E.: "Experimental Study of Pressure Gradients Occurring During Continuous Two-Phase Flow in Small Diameter Vertical Conduits," JTP, Apr., 1965.

Orkiszewski

The Orkiszewski correlation was developed for the prediction of two phase pressure drops in vertical pipe. Four flow regimes were considered: bubble, slug, annular-slug transition, and annular mist. The method can accurately predict, to within 10%, the two phase pressure drops in naturally flowing and gas lifted production wells over a wide range of well conditions. The precision of the method was verified when its predicted values were compared against 148 measured pressure drops. Unlike most other methods, liquid holdup is derived from observed physical phenomena, and is adjusted for angle of deviation.

| Orkiszwski, J.: "Predicting Two-Phase Pressure Drops in Vertical Pipe," JPT, June, 1967. |

Duns & Ros

The Duns & Ros correlation was developed for vertical flow of gas and liquid mixtures in wells. Equations were developed for each of three flow regions, (I) bubble, plug and part of froth flow regimes, (II) remainder of froth flow and slug flow regimes, (III) mist flow regime. These regions have low, intermediate and high gas throughputs respectively. Each flow region has a different holdup correlation. The equations were based on extensive experimental work using oil and air mixtures.

| Duns, H. and Ros, N. C. J.: "Vertical Flow of Gas and Liquid Mixtures in Wells," Proceedings, 6th World Petr. Congress, Frankfurt, Germany, 1963. |

Aziz

The Govier, Aziz & Fogarasi correlation was developed following a study of pressure drop in wells producing gas and condensate. Actual field pressure drop v. flowrate data from 102 wells with gas-liquid ratios ranging from 3,900 to 1,170,000 scf/bbl were analyzed in detail. The phase conditions in the well bore were determined by standard flash calculations. Pressure-gradient data for flow under single-phase conditions were compared with conventional predictions, and found generally to confirm them. For the test in which two-phase conditions were predicted throughout the well bore, the field data were compared with several wholly empirical prediction methods, with a previously proposed method, and with a new prediction method partly based on the mechanics of flow. The new prediction method incorporates an empirical estimate of the distribution of the liquid phase between that flowing as a film on the wall and that entrained in the gas core. It employs separate momentum equations for the gas-liquid mixture in the core and for the total contents of the pipe.

Aziz, K., Govier, G. W., and Forgarasi, M.: "Pressure Drop in Wells Producing Oil and Gas," J. Cdn. Pet. Tech., July-Sept., 1972.

Beggs & Brill

Original

The Beggs & Brill correlation was developed following a study of two-phase flow in horizontal and inclined pipes. The correlation is based upon a flow regime map which is first determined as if the flow was horizontal. A horizontal holdup is then calculated by correlations, and this holdup is corrected for the angle of inclination. The test system included two 90 ft long acrylic pipes, winched to a variable elevation in the middle, so as to model incline flow both upwards and downwards at angles of up to 90°.

Revised

The following enhancements to the original method are used; (1) an extra flow regime of froth flow is considered which assumes a no-slip holdup, (2) the friction factor is changed from the standard smooth pipe model, to utilize a single phase friction factor based on the average fluid velocity.

Beggs, H. D. and Brill, J. P.: "A Study of Two-Phase Flow in Inclined Pipes," JPT, May, 1973.

Mukherjee & Brill

The Mukherjee & Brill correlation was developed following a study of pressure drop behaviour in two-phase inclined flow. For bubble and slug flow, a no-slip friction factor calculated from the Moody diagram was found adequate for friction head loss calculations. In downhill stratified flow, the friction pressure gradient is calculated based on a momentum balance equation for either phase assuming a smooth gas-liquid interface. For annular-mist flow, a friction factor correlation was presented that is a function of holdup ratio and no-slip Moody friction factor. Results agreed well with the experimental data and correlations were further verified with Prudhoe Bay and North Sea data.

Mukherjee, H.: "An Experimental Study of Inclined Two-Phase Flow," Ph. D. Thesis, Univ. of Tulsa, 1979.

Gray

Another method for taking into account the effects of liquids in gas wells was developed by Gray and is recommended by the API in their manual for sizing subsurface safety valves, manual 14BM, API 14B. The liquid holdup was correlated with two dimensionless numbers and the no-slip holdup. The accuracy of the Gray method was stated to be questionable if:

-![]()

- d > 3.5 in

-Liquid/gas ratio> 50 bbl/Mmscf

-Water/gas ratio> 5 bbl/Mmscf

In practice, the Gray method has been found to give good results for conditions well out of these ranges.

Gray, H. E.: "Vertical Flow Correlations in Gas Wells," User Manual, API 14-B SSSV Computer Program.

Mona Coefficients

Click link for more information

Modified Gray

see Gray

DunsRosGray

see Duns & Ros and Gray

Stoisits

Developed by Rich Stoisits (ARCO) as a mechanistic model before Ansari was available. Retained for posterity.

Cullender & Smith

For use in gas only systems

Water Only

Fundamental flow Moody Friction Factor- no gas

Ansari

The Ansari model was developed as part of the Tulsa University Fluid Flow Projects (TUFFP) research program. A comprehensive model was formulated to predict flow patterns and the flow characteristics of the predicted flow patterns for upward two-phase flow. The comprehensive mechanistic model is composed of a model for flow pattern prediction and a set of independent models for predicting holdup and pressure drop in bubble, slug, and annular flows. The model was evaluated by using the TUFFP well databank that is composed of 1775 well cases, with 371 of them from Prudhoe Bay data.

OLGA Steady State

OlGAS is based in larger part on data from the SINTEF two-phase flow laboratory near Trondheim, Norway. The test facilities were designed to operate at conditions that approximated field conditions. The test loop was 800 m long and 8 inches in diameter. Operating pressures between 20 and 90 barg were studied. Gas superficial velocities of up to 13 m/s, and liquid superficial velocities of up to 4 m/s were obtained. In order to simulate the range of viscosities and surface tensions experienced in field applications, different hydrocarbon liquids were used (naptha, diesel, and lube oil). Nitrogen was used as the gas. Pipeline inclination angles between 10 were studied in addition to flow up or down a hill section ahead of a 50m high vertical riser. Over 10,000 experiments were run on this test loop during an eight year period. The facility was run in both steady state and transient modes. OLGAS considers four flow regimes: stratified, annular, slug and dispersed bubble flow and uses a unique minimum slip criteria to predict flow regime transitions.

Chokshi

A flow pattern free pressure gradient and liquid holdup correlation This subroutine calculates two Phase liquid holdup and pressure gradient using a statistical correlation developed from test well data. The English system of units is used.

Written by: Rajan N Chokshi 1st version: Jan 1993

Revised by: Rajan N Chokshi Last revision: Aug 1994

Chokshi, R. N.: "Prediction of Pressure Drop and Liquid Holdup in Vertical Two-phase Flow through Large Diameter Tubing," Ph.D. Dissertation, The University of Tulsa (1994)

Horizontal Correlations:

Dukler

The Dukler method has been widely used in the petroleum and pipeline industries and gives good results for both small and large diameter pipelines. Although no effect of pipeline inclination is included in the method, it has been successfully combined with a method proposed by Flanigan for hilly terrain pipelines.

Dukler, A. E., et al.: "Gas Liquid Flow in Pipelines, I. Research Results," AGA-API Project NX-28, May, 1969.

Beggs & Brill

Original

The Beggs & Brill correlation was developed following a study of two-phase flow in horizontal and inclined pipes. The correlation is based upon a flow regime map which is first determined as if the flow was horizontal. A horizontal holdup is then calculated by correlations, and this holdup is corrected for the angle of inclination. The test system included two 90 ft long acrylic pipes, winched to a variable elevation in the middle, so as to model incline flow both upwards and downwards at angles of up to 90°.

Revised

The following enhancements to the original method are used; (1) an extra flow regime of froth flow is considered which assumes a no-slip holdup, (2) the friction factor is changed from the standard smooth pipe model, to utilize a single phase friction factor based on the average fluid velocity.

Beggs, H. D. and Brill, J. P.: "A Study of Two-Phase Flow in Inclined Pipes," JPT, May, 1973.

Mukherjee & Brill

The Mukherjee & Brill correlation was developed following a study of pressure drop behaviour in two-phase inclined flow. For bubble and slug flow, a no-slip friction factor calculated from the Moody diagram was found adequate for friction head loss calculations. In downhill stratified flow, the friction pressure gradient is calculated based on a momentum balance equation for either phase assuming a smooth gas-liquid interface. For annular-mist flow, a friction factor correlation was presented that is a function of holdup ratio and no-slip Moody friction factor. Results agreed well with the experimental data and correlations were further verified with Prudhoe Bay and North Sea data.

Mukherjee, H.: "An Experimental Study of Inclined Two-Phase Flow," Ph. D. Thesis, Univ. of Tulsa, 1979.

Dukler & Eaton

Eaton correlations for friction factor and liquid holdup resulted from extensive data that were obtained from a test facility that consisted of two 1700 ft lines. Diameters of 2-in and 4-in were utilized, and three liquids were used in each line. The variables studied and their ranges were: gas rate (0-10 Mmscfd), liquid rate (50-5500 STB/day), liquid viscosity (1-13.5 cp), and system pressure (70-950 psig). The friction factor and liquid holdup were correlated with dimensionless numbers using regression analysis. Liquid holdup was measured by trapping a segment of the flow stream between quick-closing valves. Flow pattern was not considered in the correlation, and no effect of pipe angle is included. The liquid holdup correlation is considered to be one of the best available for horizontal flow, but the friction factor correlation does not degenerate to the single-phase case as the flow approaches either all liquid or all gas. In the range of low gas-liquid ratios, the friction factor becomes very large. It has been found that the friction factors will be valid if the value of the abscissa correlating group falls between about 10^4 and 10^6. Also see Dukler.

Minami - Beggs - Brill

Additional updates

Other Non-Snap Correlations:

NoSlip

The NoSlip correlation assumes homogeneous flow with no slippage between the phases. Fluid properties are taken as the average of the gas and liquid phases and friction factors are calculated using the single phase Moody correlation.

BJA for Condensates

Baker Jardine & Associates have developed a correlation for two phase flow in gas-condensate pipelines with a no-slip liquid volume fraction of lower than 0.1. This model represents no major advance in theory, but rather a consolidation of various existing mechanistic models, combined with a modest amount of theoretical development and field data testing. The model uses the Taitel Dukler flow regime map and a modified set of the Taitel Dukler momentum balance to predict liquid holdup. The pressure loss calculation procedure is similar in approach to that proposed by Oliemans, but accounts for the increased interfacial shear resulting from the liquid surface roughness.

AGA & Flanigan

The AGA & Flanigan correlation was developed for horizontal and inclined two phase flow of gas-condensate gathering systems. The Taitel Dukler flow regime map is used which considers five flow regimes: stratified smooth, stratified wavy, intermittent, annular dispersed liquid, and dispersed bubble. The Dukler equation is used to calculate the frictional pressure loss and holdup, and the Flanigan equation is used to calculate the elevational pressure differential.

Oliemans

The Oliemans correlation was developed following the study of large diameter condensate pipelines. The flow regime is predicted using the Taitel Dukler flow regime map, and a simple model, which obeyed the correct single phase flow limits, was introduced to predict the pressure drop. The model was based on a limited amount of data from a 30-in, 100-km pipeline operating at pressures of 100 barg or higher.