TANK©

Reservoir Performance Analysis & Prediction Tool

TANK© is a powerful analytical tool for reviewing and predicting the performance of combination drive oil and gas reservoirs. TANK© couples a general form of the material balance equation with a choice of analytical aquifer models, allowing it to handle a wide range of hydrocarbon fluid types and reservoir drive mechanisms. Given a reservoir’s performance history, TANK© can be used to estimate original hydrocarbons in place and aquifer size and strength. Once these parameters have been quantified, TANK© may be used to review and predict reservoir and aquifer performance using a variety of analytical techniques.

Reservoir & Hydrocarbon Fluid Considerations

TANK© includes PVT options and material balance formulations that allow it to handle a wide range of hydrocarbon fluid types and reservoir drive mechanisms.

Hydrocarbon Fluid Types

TANK©’s hydrocarbon fluid type options include dry gas, wet gas, retrograde gas, and black oil. In wet and retrograde gas reservoirs,TANK© automatically converts condensate production to its gas equivalent prior to material balance calculations, then splits the total calculated original gas in place into residue gas and condensate. In volatile oil reservoirs, TANK© may used to analyze performance at reservoir pressures above the bubble-point. Black oil reservoirs may be either initially saturated or under-saturated, with an option for a primary gas cap.

Reservoir Drive Mechanisms

TANK© supports a full range of reservoir drive mechanisms, from a simple volumetric gas reservoir to a complicated combination drive oil reservoir with a primary gas cap, an unsteady-state aquifer, and a pressure-dependent pore volume compressibility. TANK© will also handle immiscible gas and water injection operations. TANK© is not an appropriate tool for evaluating miscible injection processes. However, TANK© can and should be used to analyze the primary and secondary depletion histories of these reservoirs prior to compositional modeling of enhanced recovery operations.

Determination of OHIP & Aquifer Description

The first step of a typical TANK© analysis uses the production, injection, and average reservoir pressure histories of a reservoir to look for evidence of water influx and estimate original hydrocarbons in place using material balance regression analysis. If an aquifer is present, TANK© couples a choice of analytical aquifer models with the material balance equation to simultaneously determine original hydrocarbons in place and aquifer constants.

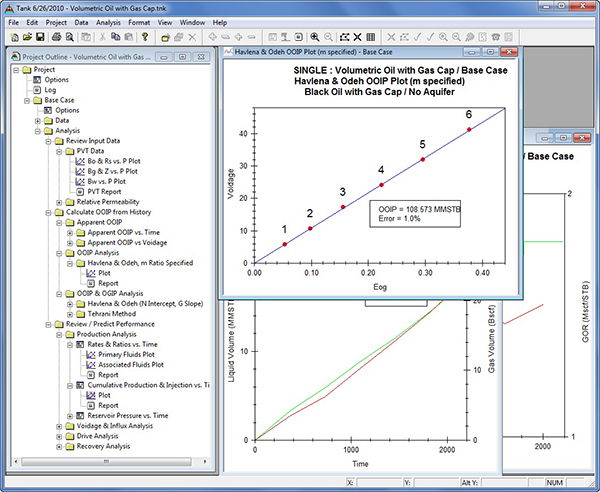

OHIP Regression Analysis Techniques

TANK© offers a total of 30 different volumetric and water-drive OHIP regression analysis techniques. Between four and nine of these techniques will be available for a particular reservoir, depending on its drive mechanisms and the hydrocarbon fluid type. Conventional analysis techniques include the Campbell and Cole apparent hydrocarbons in place plots for identifying water influx, p/z decline analyses for gas reservoirs (standard, over-pressured, and water-drive), Havlena & Odeh straight-line analysis techniques, Tehrani voidage minimization techniques, and the Roach method for analyzing high pressure gas reservoirs.

In addition to conventional analyses, TANK© offers several analysis techniques developed by Mr. Steven Sills and available only in TANK©. These include a suite of CARET analysis techniques for water-drive OHIP determination and the Sills method for simultaneous determination of OOIP and pore volume compressibility in volumetric oil reservoirs.

Analytical Aquifer Models

TANK© offers a comprehensive list of analytical aquifer geometries and flow models. Aquifer geometries include radial, linear, and bottom-water. Aquifer flow models include small pot, steady-state (Schilthuis or Fetkovich), unsteady-state (van Everdingen & Hurst), and pseudo steady-state (Fetkovich). Unlike some other material balance applications, all three geometries are available for every flow model with the exception of the Fetkovich models, for which bottom-water solutions were not published. Finite no-flow outer boundary aquifer solutions are included for all unsteady-state flow models. A constant-pressure outer boundary option is available for the linear Fetkovich unsteady-state aquifer solution.

Review & Prediction of Reservoir & Aquifer Performance Review & Prediction of Reservoir & Aquifer Performance

TANK© also offers performance analyses for reviewing and predicting reservoir and aquifer performance. The simplest analyses are based only on the reservoir pressure and production histories and can be performed as soon as this information has been entered. Others require estimates of OHIP and the aquifer description to back-calculate the reservoir pressure and water influx histories from the reservoir’s production history. For these analyses, TANK© can use the OHIP value and aquifer description determined from a material balance regression analysis. TANK©’s performance analyses focus on four aspects of reservoir and aquifer performance: production trends, voidage and influx relationships, reservoir drive mechanisms, and recovery trends.

Production Analyses

Production analyses include plots of production and injection rates and ratios vs. time, cumulative production and injection vs. time, and the observed reservoir pressure history. If OHIP and aquifer constant values have been entered or saved from the results of an OHIP regression analysis, a reservoir pressure history calculated from the production history may also be displayed. If estimates of future production and injection volumes vs. time are specified, TANK© will predict future reservoir pressure vs. time.

Voidage and Influx Analyses

Voidage and influx analyses include plots of reservoir voidage and calculated water influx rates vs. time. Cumulative voidage and influx volumes vs. time may also be reviewed. TANK© will also predict future water influx rates for user-specified off-take and injection scenarios.

Drive Analyses

Drive analyses include plots of historical and predicted cumulative and incremental reservoir drive indices vs. time, aquifer and gas cap sweep efficiency vs. time, and reservoir fluid volumes vs. time. These analyses indicate the relative strengths and efficiencies of reservoir drive mechanisms and how they change with time. In water-drive gas reservoirs, for example, these drive analyses can quantify the recovery benefits of increasing voidage rates to minimize cumulative aquifer influx and reservoir pressure at abandonment. Recovery Analyses Recovery analyses include plots of reservoir pressure vs. recovery, WOR vs. recovery, and recovery vs. aquifer influx and injection. These analyses are particularly useful for surveillance of oil reservoirs produced under natural water drive or during water-flood operations.

Theory

TANK© performs calculations using the general material balance equation. If an aquifer is present, TANK© calculates water influx volumes using an analytical aquifer model. TANK© solves the material balance and aquifer influx equations in different ways depending on the type of analysis being performed.

The General Material Balance Equation

TANK© uses a general form of the material balance equation to relate the change in a reservoir’s average pressure to the original oil and free gas volumes in place and the reservoir’s production and injection history:

F = N(Eo + Efwo) + G(Eg + Efwg) + We

Analytical Aquifer Calculations

When an aquifer is present, TANK© evaluates the water influx term using an analytical aquifer model of the form

:

We = U * S

The definitions of the aquifer influx constant, U, and the aquifer influx variable, S, depend on the aquifer geometry and flow type selected by the user.

TANK© was developed by Mr. Steve Sills and Mr. Michael Perry